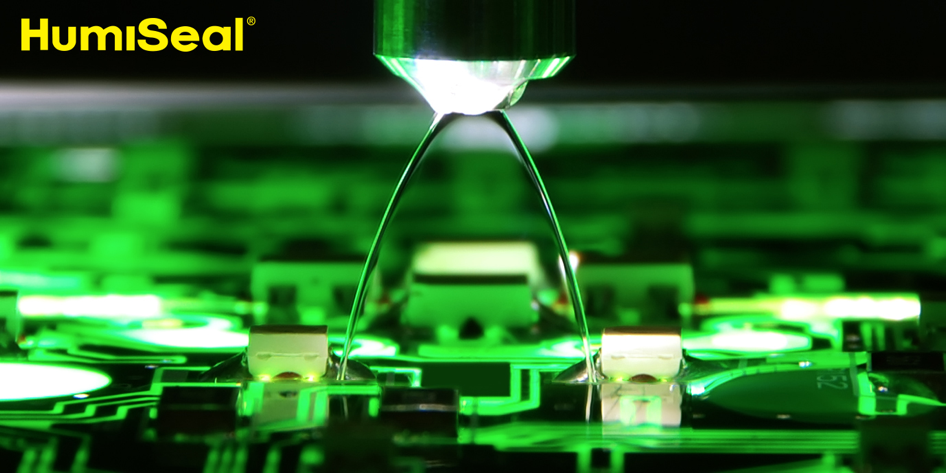

Compressed air; one of the basic components used in most automatic or semi-automatic conformal coating processes! Pressurized air moves the liquid coating from the tank, through the hoses and the valves onto the PCB. Since the pressurized air makes direct contact with the conformal coating, there are critical properties that must be taken into consideration, especially with moisture sensitive materials. What critical factors are important when working with UV40, UV500, 1A20 or any RTV Silicone from HumiSeal?

Three important variables to consider:

- Pressure – It’s a critical component of the dispensing process. Inaccurate pressure will cause a variety of defects such as inadequate coverage, over spray, air bubble incorporation, flooding, and many others.

- Oil-free – Air source and compressor must output oil-free air. Oil will cause dewetting and adhesion loss.

- Dryness – Due to the moisture cure mechanism of RTV coatings, it is critical that the pressurized air is dry to avoid any premature curing. This will affect viscosity, adhesion, and liquid surface tension – all key properties for proper wetting.

The Importance of Dry Air

If you are already using, or plan on using, any type of moisture sensitive conformal coating, you should be aware of the absolute need for clean and dry air. This is because moisture containing air will cause premature curing.

The cure mechanism of the RTV coating relies on ambient humidity to catalyze the polymerization reaction of the resin system. In other words, a water molecule reacts with active sites within the liquid coating to chemically cross-link the resin. This results in formation of highly dense molecular chains.

Ideally, this reaction needs to happen only after the coating has been applied on the PCB, and not within the coating equipment.

There are two types of conformal coating cure systems that use moisture to complete polymerization:

Pure RTV urethanes and silicones that use only atmospheric moisture to cure UV curable systems which use moisture as a secondary mechanism to complete the overall cure, as well as to cure those areas not directly exposed to the UV during the curing process. These are also customarily known as the “shadowed areas”.

The ultimate goal is to prevent conformal coatings from coming into contact with moisture and contaminated air.

Possible defects from moisture containing air include:

- Coating appears cloudy

- Premature cure in valves, hoses, and reservoir

- Bubbling

- Viscosity creep

- Adhesion loss

- Pinholes

Conclusion:

The best two ways to ensure that your process runs smoothly are to either install a desiccator unit or to use dry compressed air source such as Nitrogen. The operators should be trained in recognizing signs of moist air in the conformal coating process to prevent poor coating quality.

If you have additional questions regarding defects in your conformal coating, please don’t hesitate to contact us.