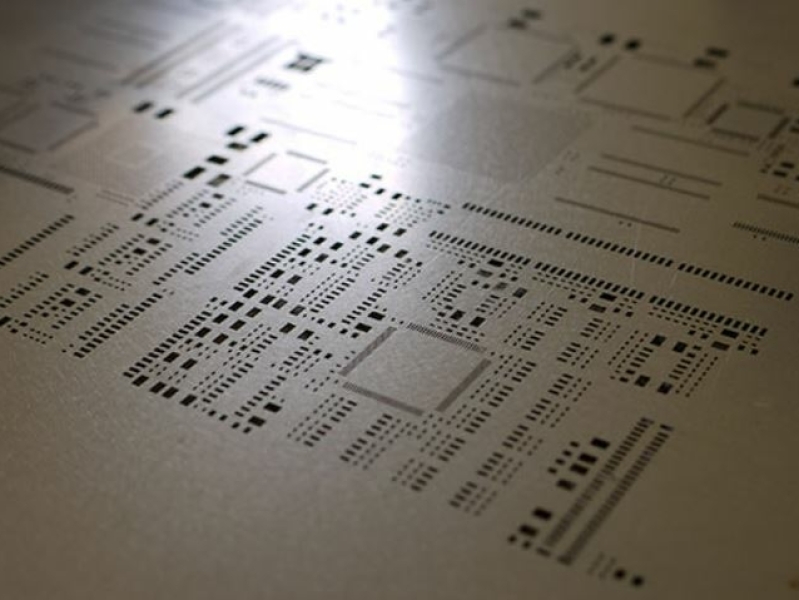

For some application it is required to clean PCB's prior to Printing or after Soldering. Defects in solderjoints can be avoided by cleaning the boards before entering the Stencil Printer. Cleaning after soldering might be required to remove flux residues or to prepare your boards before applying a Conformal Coating Layer. We offer a wide range of Cleaning Solutions, both Equipment and the required Cleaning Agents.

Cleaning Solutions

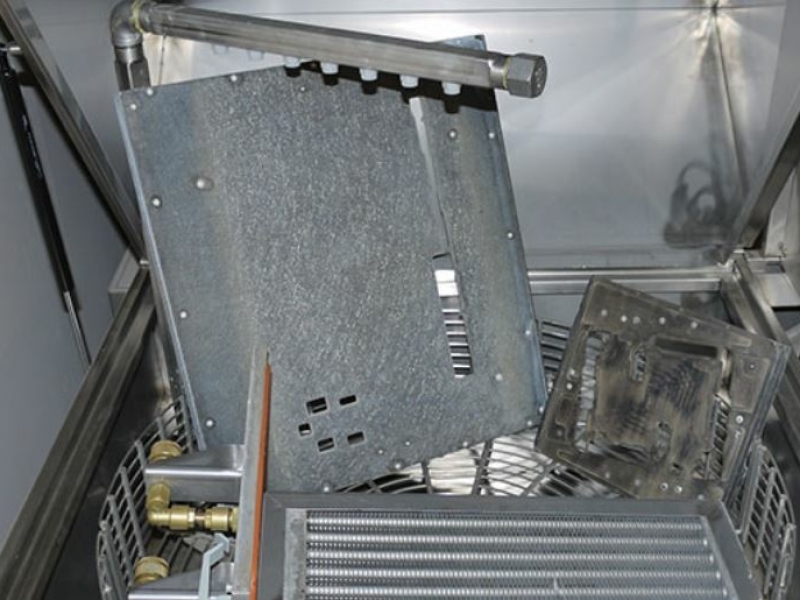

MB Tech - Cleaning Equipment

MBtech designs and manufactures cleaning equipment that meets the highest standards of the Semiconductor and Electronic Industries. By focusing on customer’s needs, MBtech has succeeded in imposing itself as the cleaning partner of the biggest industrial companies as well as of innovative small businesses concentrated on high-quality production. MBtech offers concrete solutions to all the problems met in the cleaning process of stencils, electronic boards, wafers, lead frames , solder carriers, coating carrier, condensation traps andso on. Customer are active in different demanding industrial fields such as aeronautics, automotive, military, communication industry, medical, semiconductors etc.

MBtech offers solutions for:

1. Cleaning of Stencils, Squeegees and Misprinted boards

2. Removing of flux residue after soldering, such as on PCBAs, Wafers, Lead Frames and Power modules

3. Cleaning of Solder Pallets, Condensation traps, Heat Exchangers, Coating Frames and other parts.

ZESTRON - Cleaning Agents

ZESTRON offers the world’s leading cleaning media, but even more important focused on being an architect for reliable cleaning processes within electronic and metal parts cleaning applications. ZESTRON’s goal is to always provide always a cleaning process in which the quality of the cleaning result is the same after 300,000 cycles as it was at the initial start-up, irrespective of quantity and performance requirements.

MBtech equipment is designed to work in combination with ZESTRON Cleaning Agents

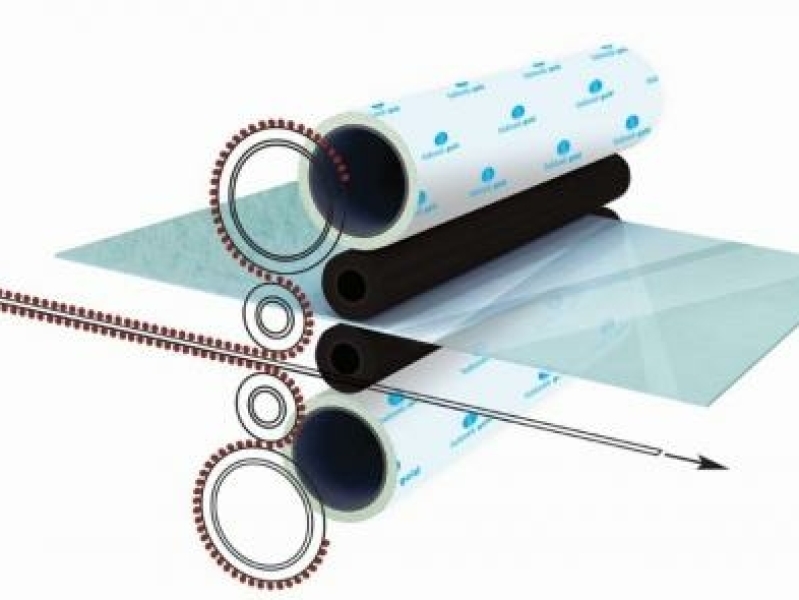

Teknek Board and Web Cleaning

For PCBA assembly TEKNEK offers contact cleaning equipment that efficiently removes potential contamination, such as glassfibers and dust, prior to entering the stencil printing process.

MBtech Flux Cleaning System