HumiSeal’s Synthetic Rubber Conformal Coating products are unique formulations that enable the user to achieve specific environmental / protection goals which are not offered by the ‘traditional’ coatings.

Would Synthetic rubber be a better fit for your application?

Synthetic Rubber materials are characterized by extremely low glass transition temperatures which resulting in a stable modulus over a wide temperature range and extreme flexibility.

Synthetic Rubber Conformal Coating is developed to withstand the demanding conditions in the most severe environments which are required in today’s applications. It provides higher operating temperature and exhibits superior mechanical properties when compared to traditional materials. Maybe Synthetic Rubber Conformal Coatings is less known, but HumiSeal have been used and developed this kind of coatings for many years and improved varieties of this Chemistry.

What is the advantages of using Synthetic Rubber Conformal Coatings

The requirements posed upon conformal coatings are changing as the pitch and packing density of electronics continues to miniaturize as a function of form factor and increased functionality. Increased operating temperature requirements along with an increase in long-term assembly reliability demands are becoming more prevalent. As a result, HumiSeal has introduced a range of synthetic rubber products that exhibit superior performance in these challenging conditions. These products have gained significant global qualifications especially in the automotive industry.

Synthetic rubber copolymers contain specifically formulated blocked alkenes. These materials are extremely flexible and yielding under various temperatures, additionally they offer superior moisture protection. This translates to greater reliability testing performance as the material “flexes” and “recovers” under various stresses during thermal shock and thermal excursion testing. Furthermore, susceptibility to dendritic growth is minimized with the use of synthetic rubbers due to superior Moisture Vapor Permeability (MVP) resistance performance. The combination of ionic contaminations and water vapor leads to dendritic growth. Synthetic Rubber Conformal Coating provide the industry’s lowest moisture infiltration rate.

Where most applications require a maximum constant operating temperature of 125°C, the solvent based acrylics and polyurethane technologies are well suited. The synthetic rubber constant operating temperature range varies greatly up to 150°C. These materials behave very well in a wide range of temperatures due to the unmatched thermo-mechanical properties.

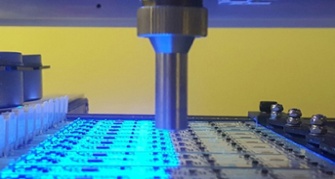

Synthetic rubber materials are solvent based and can be applied using the same process equipment as used with existing acrylic/polyurethane. Therefore, the upgrade to a higher performance material can be done without needing to change the process equipment and unlike UV curable conformal coatings, synthetic rubbers do not require capital investment in a UV oven, special handling requirements, lighting, etc.

The advantages are;

- High elongation (300 to 500%) provide protection during large temperature excursions

- Higher operating temperature range provides improved performance over standard coatings to address high temperature operating environments

- Low Youngs modulus (Yg) and low coefficient of thermal expansion (CTE). This allows for the benefit of a lower stress on components during thermal exposure testing

- Excellent adhesion to various type of substrates gives user wider application window

- Excellent moisture protection due to low moisture vapour permeability (MVP) reduces the potential for dendritic growth

The process advantages are;

- Versatile application methods (selective, spraying, dipping, brushing) allow for more cost efficient equipment selection and investment

- Increased compatibility with no-clean process compared with traditional technologies

- Fast drying by solvent evaporation for high throughput during manufacturing

- Easy to rework in case removal is required

Synthetic rubbers meet the requirements of IPC-CC-830 as well as many automotive OEM standards. They are also UL 94 rated for flammability.

Still struggling to overcome high reliability requirements?

Your answer may lay with Synthetic Rubber Conformal Coatings. It offers a much higher performance solution and add value to printed circuit assembly reliability without the need to change the exising process equipment.

We recommend talking to one of our experienced team to confirm the selection and dicuss your particular needs in more detail. Please contact us of check our Website for more information which make you certain of always using the best coating for your application!