Daan’s Tips & Tricks

Offline work preparation:

In many companies, a lack of engineering capacity and pressure on delivery times create major bottlenecks. This often results in incomplete work preparation before jobs are transferred to the SMD production line. If a job is not 100% prepared in advance, additional required programming work at the line should be accounted for during planning. Failure to do so will cause unforeseen delays at the start of production, significantly disrupting subsequent production steps. This will not only result in longer delivery times but might also affect the quality of the end product.

On-time parts supply:

Similar issues arise when the logistic flow is not aligned with production planning. Timely material supply should allow operators to prepare feeder kits in advance to avoid long machine stoppages during job changeovers. Good part supply before and during production will result in higher equipment utilization and increased production output.

Smart software:

Smart software tools and integrated connections between systems like ERP, MES, and machine software can contribute to better visibility of the current state of production and component availability in production and warehouses. This enables more accurate and predictable planning. Modern software can even recommend the best production order and cluster jobs to reduce the number of changeovers. As a result, overall equipment efficiency and output are increased, and less operator time is required.

Preventive maintenance:

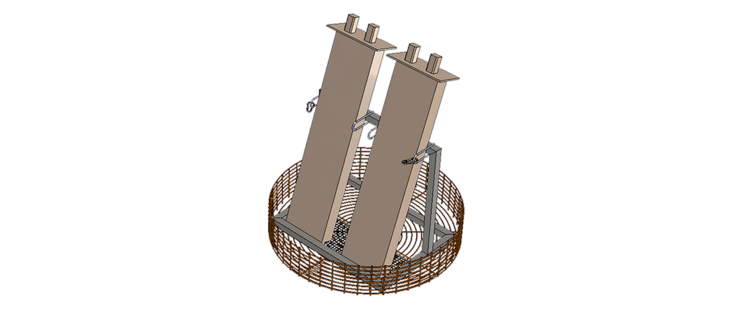

Preventive maintenance is frequently not executed on time due to production pressure, sometimes caused by issues as described above. However, this can result in unplanned machine breakdowns, further exacerbating capacity problems. A typical example is the cleaning of machine parts such as filters, oven radiators, or pallets used in soldering and coating equipment. Cleaning is a dirty and time-consuming task that operators dislike and tend to delay. However, using the right tools and chemicals can simplify the job and improve cleaning results.

MB-Tech offers the MC200 parts cleaning machine, specifically designed to simplify and improve this maintenance task. Zestron offers cleaning fluids, such as Atron SP300, that work perfectly in this machine. They also offer chemicals for those who prefer manual cleaning, providing a significant improvement.

All the points mentioned might seem obvious, but as noted, we often see issues arise in the field. Many problems can be avoided with some extra attention or a small investment.

Please contact me if you would like to learn more.

Daan van Hoogstraten