Does your conformal coating not wet properly? Do you struggle with craters, fish-eyes, or film separation? The culprit could be that the surface energy of your PCB is lower than the surface tension of the conformal coating. The above defects are discussed frequently with customers on our technical support line, and any time we receive a technical enquiry regarding poor wetting or loss of adhesion, we ask “what is the surface energy of your substrate?” In this blog, we will explain surface energy, surface tension, and how to quickly troubleshoot defects resulting from low surface energy.

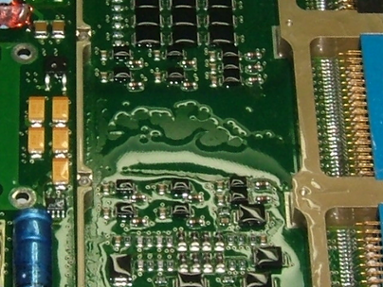

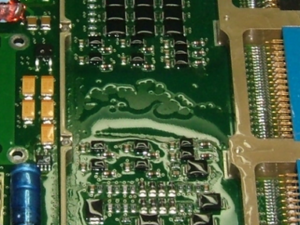

Figure 1. Conformal coating de-wetting due to low surface energy

Surface energy is a parameter that significantly affects the wetting characteristics of the conformal coating. It also impacts the adhesion of the cured coating to the substrate. Therefore, your efforts to achieve highest possible surface energy will result in a cured conformal coating that is smooth, clean, and with optimal adhesion to the PCB.

How to quickly measure surface energy in production environment?

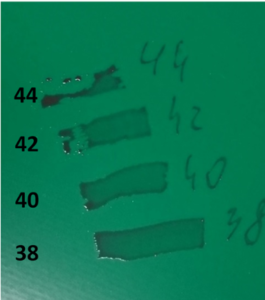

Dyne level test – This is the most common method of surface energy measurement and it is a simple comparative test by using dyne pens. Dyne pens contain a variety of solutions with predetermined surface tension characteristics. In this test the unknown surface energy is referenced by the known surface tension of applied solution and is expressed as dynes/cm. Good wetting of the solution is ensured when surface energy of the substrate is equal to or higher than the surface tension of applied test liquid. Please reference Dyne pen manufacturer’s procedure for proper use. Other methods of surface energy measurements are Cotton Swab applicator method, Draw-Down application method, and contact angle measurement.

Figure 2. Surface energy measured by felt tip Dyne Pens 38-40 dynes/cm

The most common dyne pen solution packs sold contain pens in the range of 30 – 44 dynes/cm. The dyne level test is relatively simple, quick and inexpensive.

For optimum wetting and adhesion of coating onto substrate the minimum recommended level of surface energy is 38 dynes/cm. This value should be achieved after the manufacturing process of PCB prior to conformal coating. For example, solder reflow may have a negative impact on the surface energy. The type of flux and amount of residues left on the surface will inhibit the wetting of conformal coating by lowering surface energy of the substrate. Improper handling of the assembly throughout the manufacturing process will also have negative impact on surface energy. Furthermore, surface energy level of incoming boards from board manufacturer may be too low. Desired surface energy level should be part of the incoming board specification and incoming inspection. If surface energy is below 38dynes/cm on the incoming boards, it will be hard to improve this value after assembly process prior to conformal coating.

Preventive measures to ensure optimal surface energy:

- A minimum level of 38 dynes/cm may have to be specified as the part of PCB requirements to manufacturer

- Testing of surface energy after each assembly process step

- Optimization of handling with proper protective equipment

- Reduction of hand lotions and perfumes in manufacturing areas, or surface modifiers that could negatively impact the wetting profile of the soon to be coated substrate

- Removal of silicone compounds near conformal coating areas. These include silicone conformal coatings and lubrication sprays, greases, oils, etc.

- Reflow process optimization for complete activation of flux and minimization of flux active residues

Four common methods to improve surface energy in such circumstances are:

- Simple DI wash to remove minor water soluble residues and dust

- Solvent wash or wipe when there are minor localized residues resistant to just DI water

- Saponifier assisted wash to wash away tougher residues such as flux, oils, and stains

- Plasma treatment to remove wash resistant stains and to activate the surface with very high surface energy

Increasing and maintaining optimum surface energy will help you eliminate common defects such as craters, fish-eyes, or film separation in your conformal coating process. The best approach to eliminate these common coating defects is to ensure that you have the proper surface energy throughout every step prior to conformal coating and take appropriate action to remedy if required. Low surface energy may require cleaning of the boards prior to application of conformal coating. High surface energy will improve your coating appearance and adhesion to substrate.