PCBA Cleaning

How to clean your assembled PCB’s,. In part 3 of this trilogy, we would like to address some thoughts about PCBA cleaning.

In Europe, most customers use ‘’no clean’’ solder pastes. However, still, several applications demand cleaning, making the challenge bigger. For example, cleaning prior to applying a conformal coating or before potting is highly recommended. Any visible or no visible residues could disappear below the coating surface and cause trouble in the field, so better safe than sorry and try to get the PCB’s as clean as possible.

Selecting the right cleaning agent in combination with the right cleaning equipment however is not that easy as it is very much dependent on your type of solder paste, flux type and PCB design. The worst that can happen is that the combination of cleaning agent and cleaning method only partly removes the captured flux residues, causing more harm than good.

Partnertec is happy to work together with two of the most knowledgeable companies in the cleaning industry, Zestron and MBtech, helping us to find the right solution for your cleaning needs.

Zestron offers a wide range of cleaning agents, both water-based and semi-aqueous or water-free. They offer very strong cleaning expertise and can perform any desired test in one of their technical centre and laboratories, in the equipment of your choice.

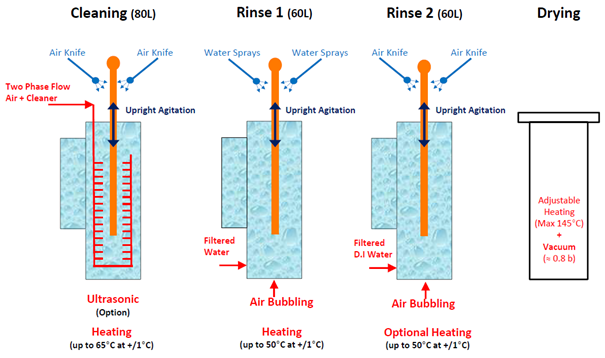

MBTech’s spray under immersion cleaning technology offers a very effective method for PCBA cleaning. The immersion in a heated bath allows Zestron’s Chemistry to soak the flux residues while the moving spray jets will add the desired mechanical force. Separate cleaning, rinsing and drying chambers in combination with closed-loop filtration on all tanks, results in the lowest possible fluid consumption. The integrated heated vacuum drying chamber will assure a 100% drying result.

Please contact us if you like to learn more about our cleaning solutions.