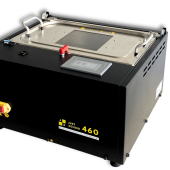

Vapor Phase Soldering is an alternative to the commonly used hot air heating technology found in reflow soldering ovens. Heat transfer occurs by placing the PCB in controlled hot vapor above a boiling inert fluid. A commonly used fluid for lead-free soldering is GALDEN© LS-230, which has a boiling temperature of 230 °C. The vapor temperature equals the boiling point, ensuring the entire PCB is heated uniformly without risk of overheating.

Because the vapor is oxygen-free, the process offers similar benefits to nitrogen soldering: improved wettability, reduced oxidation, and shinier joints. Vapor Phase Soldering delivers reliable, high-quality joints on any type of PCBA, regardless of board complexity or component mix. For low-volume production and prototype builds, Vapor Phase Soldering provides an ideal solution at an affordable cost.