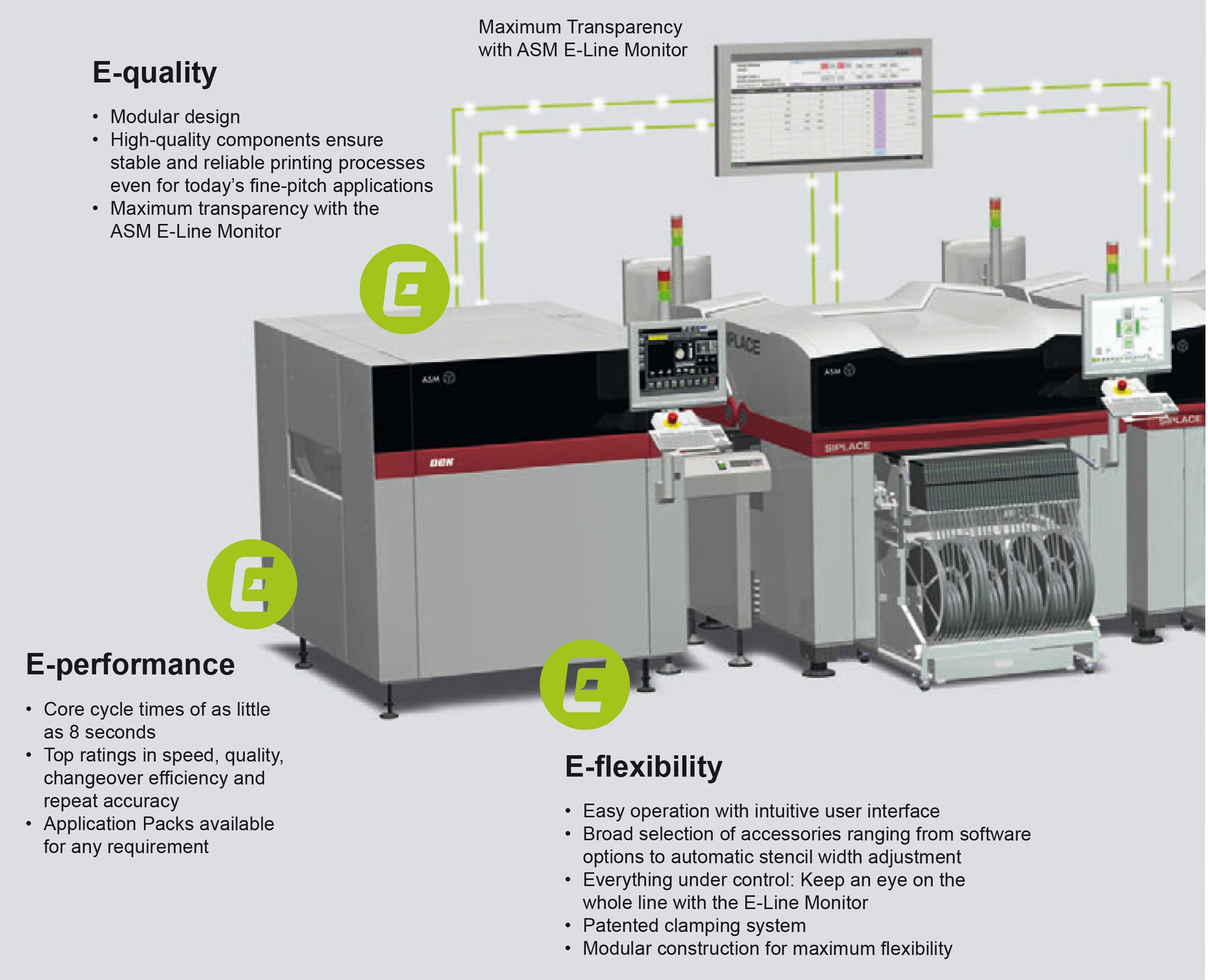

E by Dek Printing Solution

NeoHorizon Printing Solution

E by Dek is the newest member of the E Solutions from ASM. Now we can offer you a total and complete package. E by Dek can be as indiviual as your requirements.

E by DEK is as flexible as your applications and instead of investing in new printer models the E by DEK Always has the right answer thanks to a wide range of options. They have made it exceptionally flexible and will protect your investment.

Machine Performance | Specification |

| Alignment | > 2.0 Cmk @ ± 12.5 μm (± 6 sigma) |

| System alignment capability | > 2.0 Cmk @ ± 25 μm (± 6 sigma) |

| Opyimum core cycle time | 8 seconds |

| Substrate size | 50 mm (X) x 40.5 mm (Y) to 620 mm (X) x 508.5 mm (Y) |

| Operating System | Windows 7 Embedded |

| Squeegee pressure mechanism | Software-controlled, motorized with closed loop feedback |

| Stencil positioning | Semi-auto stencil load with drip tray |

| Understencil cleaning | Interchangeable understencil cleaner (IUSC), fully programmable with wet/dry/vacuum wipe |

| Adjustable-width stencil mount (AWSM) | Frame variants - fully adjustable to accommodate frame sizes in the range of 381 mm to 736 mm |

| Substrate thickness | 0.2 mm to 6 mm |

| Substrate weight (maximum) | 6 kg |

| Substrate warpage | Up to 7 mm including substrate thickness |

| Substrate fixture | Over the top clamps Edge clamps Foil-less clamps Vacuum |

| Temperature & humidity sensor | Monitoring of the process environment |

Partnertec, your partner in best all-round solutions!