A brief explanation of why X-ray component counters are becoming so popular.

Sometimes quantity matters, especially when you’re short on something. If you run out of an SMD component when you don’t expect it, it will lead to an unplanned line interruption. This can delay the delivery to your customers. However, stopping an entire SMD line in the absence of a very small SMD part is common practise. Last minute organising of missing parts can be very costly and time consuming for your logistic and procurement organisation.

Techniques to avoid machine downtime

Various techniques are used to prevent this. Most modern Pick & Place machines have software in which the user can enter the number of components as mentioned on the supplier’s label. However, not all suppliers deliver the exact quantities as ordered or mentioned on the label. So this could be the start of the problem. Also, many machines can track the number of components picked from a reel and then send this information back to your ERP system. This software should also count the number of mis-picks. However, there are no machines that can detect losses caused by human intervention while loading the feeder, troubleshooting a feeder problem or replacing a broken tape.

Most ERP systems are therefore set up in such a way that they increase the purchase order quantity by default with a predetermined loss percentage. However, when a reel is loaded multiple times onto and off a feeder, this safety stock often does not compensate for the losses. In those cases where losses are very low, over time you will have to deal with many obsolete safety stocks in your warehouse.

Stock counting, a time consuming activity isn’t it?

An important reason for many companies to frequently count their stock. By counting the remaining parts in the reel when returning to the warehouse after production or during the annual stock counting. With traditional counting methods, this is a very time consuming job that cannot be performed with too much precision. Fortunately, modern X-ray counting systems now offer a much better alternative. Imagine the annual savings if you could reduce the time to count the components on one reel from 3 minutes to about 4 seconds ……….!

X-ray counting machines use X-ray technology and advanced software algorithms to recognize how many parts are in the package. Intelligent links with your logistics software ensure that your stock is updated automatically.

You can count on us!

Nordson Dage, the number one supplier of X-ray inspection machines to the electronics assembly industry, last year acquired Optical Control, a German manufacturer of advanced X-ray counters. Their products are now fully merged into the Dage portfolio and are sold under the Dage Assure brand. Partnertec is pleased to inform you that we are now also appointed as exclusive distributor for the Dage Assure brand.

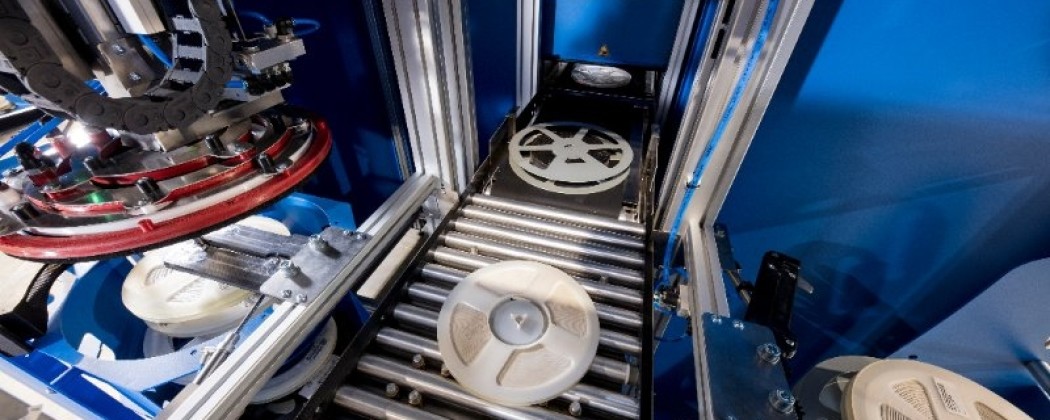

Dage Assure offers X-ray counting systems that clearly distinguish from other brands. The software offers automatic self-learning component recognition, the machines can count extremely fast and accurate, are maintenance-free and can handle any type of packaging. The machines are available with manual loading systems or with fully conveyorized automatic loading to further reduce cost of operation.

Navigate to X-ray inspection to read more about Dage Assure.

Contact us to learn more about these money-saving counting machines.