RENA have just purchased a new full production line to add to their existing two lines. RENA is a Benelux-based designer and manufacturer of LED-modules and electronic controls to numerous manufacturers of lighting and industrial equipment. Keith Bryant interviewed Jochem Winkelman, Director of Finance and responsible for production within RENA and Ralf Maas, SMT process expert, who has been in the SMT area at RENA for 19 years, and is jointly responsible for introducing the new line.

Why did you decide to increase your capacity from the two lines by adding a complete new line?

I think it was really necessary, the existing lines were quite old and with the new technologies and tighter designs, we had a lot of problems, quality issues, etc. We also want to grow our company and we needed some investments to increase our capacity and capability.

Were these problems with smaller components and accuracy or repeatability or downtime or all of these things?

First of all, placing of smaller LEDs and components. The newer generations of components were almost beyond the capabilities of our current equipment. Also the downtime of the old lines is very high. During our day shifts, the old lines are running for only about 50% of the time, the rest they stand still.

Could you talk me through your decision process?

The first thing you have to ask as a company is what do we need to buy? If you know your own specifications, it is quite easy to figure out what you need to buy. That’s the first thing that we did, to find out what we want to achieve in the coming ten years. We made the decision that first we are going to invest in capacity for the LED applications.

A lot of the LED components must be placed very accurately. When we knew all the specifications, Jochem and I investigated the brands which we believe could help us. We visited all the brands, had demos and we eventually made an informed decision.

How long was the time frame?

In September of last year, we started the process. In December, we decided to not to continue our investigation with a few of the brands we were contemplating, and in January we decided on ASM. Four weeks later we made the final decision on the whole line. This time, we did our homework. We were looking for a good OEM, good performance was one factor, along with great local support. The other is the whole smart factory concept with ASM, which is something we want to grow into. We used to have problems finding a new reel for a new production run in time and this is downtime and we do not want to have downtime.

ASM, are one of the leaders in this kind of thinking, because it is more than a process. It is actually a fundamental change in the way that the factory works and it is really all about efficiency and continual processes and minimizing costs. What was the key thing that really made you decide that ASM was the right way to go, was it the smart factory or the technology of the equipment or a mixture of the two?

A mixture of the two and because we had some demos with other brands. One of them was the brand we have now, because to change over to a new brand is also a risk. At the end of December, we basically decided that if we stay with our current brand, then the advances we would make were not that much and that was not what we wanted. If you go, as in this case, with ASM, you make huge steps, not just for our company, but also for the smaller companies in this region, because no only larger companies have invested in ASM so far. We had a very good discussion about this and were convinced that ASM would give us everything we were looking for. Of all the pieces of equipment, the ASM solution was convincing on each machine individually. Of the other alternatives they had convincing pieces, for example, on reflow, but it was less convincing in other areas of the line. With ASM if we had some questions, they were answered well when we visited their head office. Where there were discussions of technical issues and technical specifications, if they were not sure about it, they immediately called someone and a specialist came to us in the meeting and answered, this gave us a good feeling and built a strong relationship.

Did you go to see the huge ASM stand at Productronica?

Yes, very briefly. It was my first time at Productronica and my first impression was that the ASM brand is expensive, and it is, it is costly. That does not make it expensive overall however, it is costly in purchasing but not after that.

I know what you mean, it is the purchase price, but not necessarily the cost of ownership and not necessarily the value proposition when you get to the end.

If you go with cost per placement and return on investment numbers, it is a whole different story and purchase price is only a small part of the picture.

It is refreshing for a Director of Finance to say that, because normally they stop after “it is expensive.” It is nice to talk to one who understands the difference between price and cost and value. That is a good thing, and although we laugh, in some ways it goes towards understanding why you made this decision.

When we walked the floor did I see the ASM SPI machine? You must be one of the first companies to have this product. On one hand you are talking about ASM quality and reliability and you are also prepared on the back of the ASM reputation to take a key component of your production line as an almost brand new product. I know ASM have a lot of experience in vision systems but for you it is still a leap of faith, because you are buying something that you might have seen demonstrated, but you have not seen it at 20 sites around the world running well for the last two years? That is correct. At this stage, we really need an SPI, because we want to invest in quality and good process control. You can do this monitoring at the front of the line or at the end of the line, we choose to do it at the front.

To build the quality in, not inspect it out?

When we had the first demo in Munich with the Process Expert, I was really convinced that this was the way forward, because you are having control of the key part of the process.

Also, it ties in with the smart factory concept of everything linking together.

Yes, if you look at SPI there are many systems in the market that are good and are reasonably priced. It is the concept of everything connected to each other, that is why we made the choice to have a little bit of faith, we believe the SPI function of the ASM solution is going to be a key part of our process improvement plan.

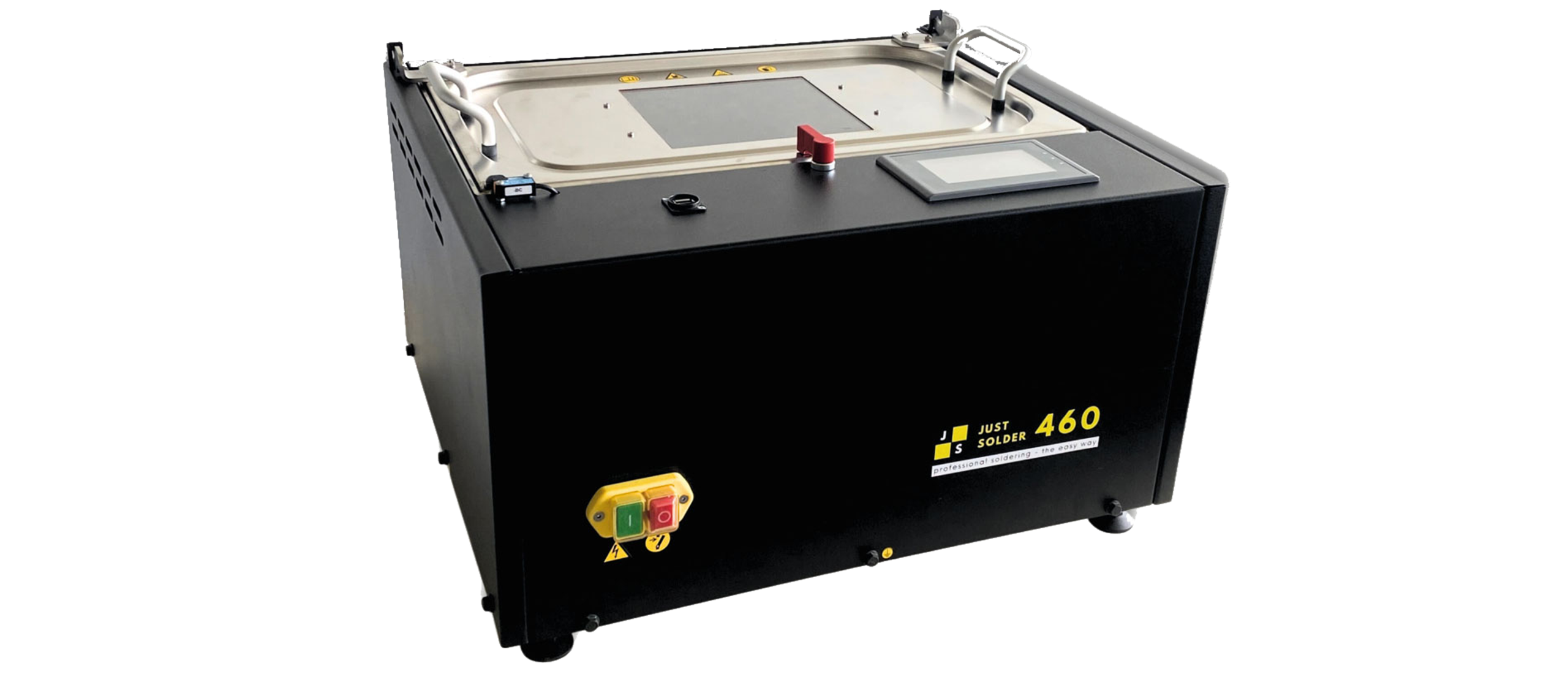

You have convinced me you have made the right decision. I only have one or two more questions. The first one is; OK, the preceding explains the ASM kit you bought. It does not explain all the non-ASM pieces, the Nutec, Vitronics Soltec and all the other kit I saw with Partnertec labels on it. Was Partnertec a by-product of the decision or did you see a real value in getting everything from one source and pulling the project together?

We wanted the whole line supported by one partner, in this case, Partnertec. We already had a long term relationship with them, which made the decision easier. Also ASM DEK was in their portfolio, so everything worked out perfectly, a sort of ‘one-stop-shop’ for everything we needed and with great support too, making the project so much easier and efficient.

It sounds like you did a lot of work upfront and when you made up your mind you were confident in your decisions. Then you became like the customers I used to love when I was selling; ‘I have made up my mind and now I would like it all tomorrow!’

I phoned Partnertec on January 5 with the good news, the next day Maurits was here, the week after that we were in Munich for two or three days demonstrating everything again and testing, then a week later we signed the agreement. One important thing is we asked if it would be possible that the whole line be operational before the end of June. Because that was the 35th anniversary of Rena and a big company event. The team did a wonderful job of making sure everything was running smoothly before the deadline.

So how are things going after the install?

I just got a look at a new machine where we have placed almost seven million components already, so that is pretty impressive.

How much do you do normally in a year with the two lines?

We have increased our capacity significantly, this one new line is doing double what the two existing lines can do. We are working now for twelve hours each day and it is still not enough, we are completely full. We have tripled our production by adding this new line and we are now also much more competitive, plus our yields have improved dramatically.

Anything else either of you would like to add?

One thing: as we said from the start, it is very important to have a strategic partnership with Partnertec and ASM. There is also trust, which is most important, you cannot do it just with a signed contract, it has worked out very well for all parties. That is very important for success with this new line and for our future expansion which will include another ASM line within 12 months, when we will move into another larger building with a more efficient layout. The future is very exciting for us. I find it funny that if you ride through the countryside here and you come to RENA, on a small industrial park in Zundert, a small town, next to the Belgian border, famous only as the birthplace of Vincent van Gogh.

Perhaps not where you would expect to find high tech industry, but our position gives us a very good and stable workforce which is also key to our growth plans. “It was refreshing to visit a smaller company investing in its future with capacity, technology and reducing the cost of manufacturing by embracing the Smart Factory concept. It shows true vision and and real understanding of future requirements for success”.

–KEITH BRYANT