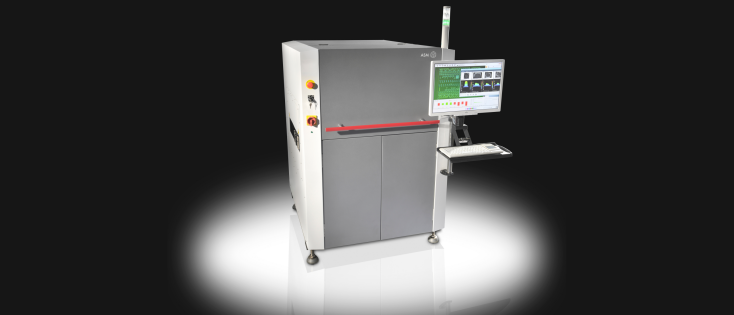

French cleaning equipment manufacturer MBtech, well known for its cleaning equipment for PCBA’s and Stencils, also offer a very efficient machine to clean mechanical parts such as Solder Carriers, Conformal Coating Carriers, Filters and various other contaminated mechanical parts.

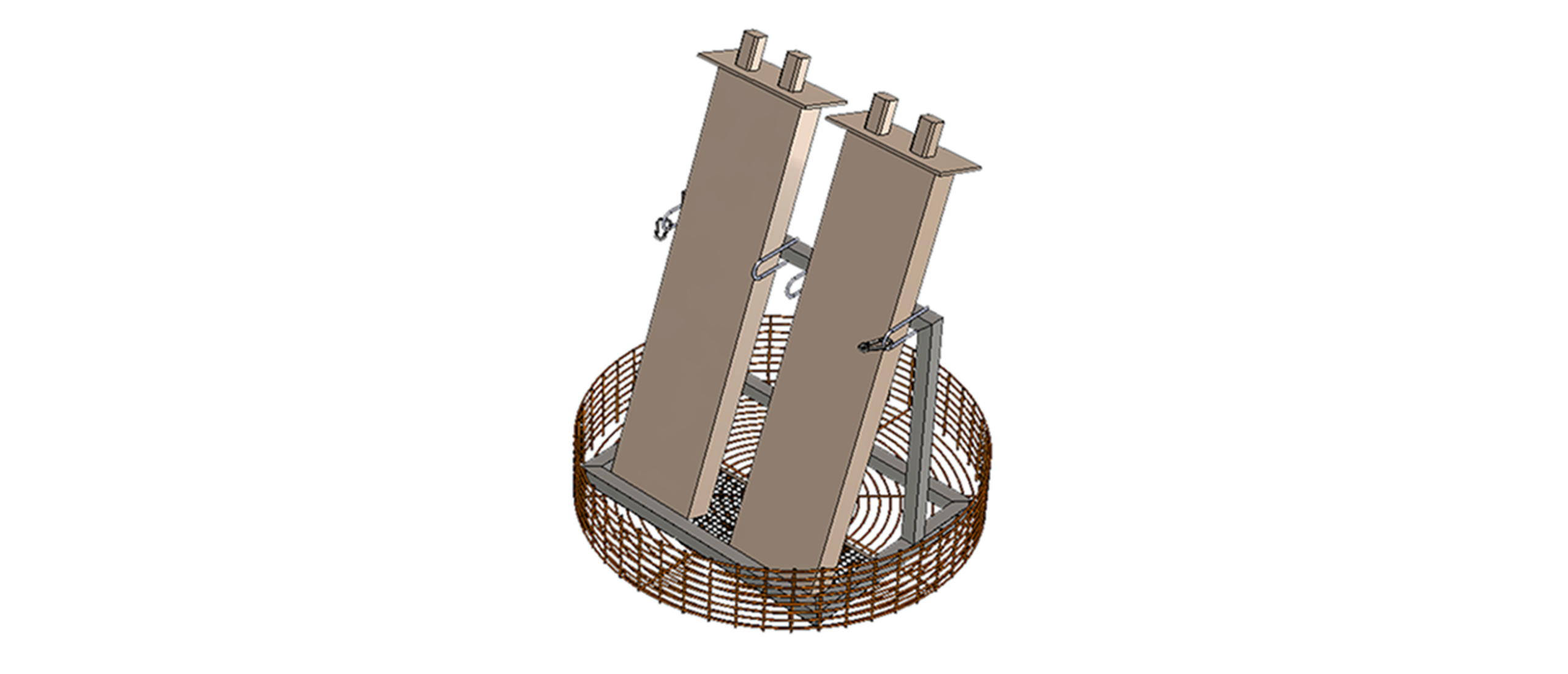

Recently a XL version of this MC200 is released that can now also hold items up to 1,2 mtr tall, including heat exchangers and flux condenser from reflow-ovens such as Vitronics Soltec Centurion and MyReflow.

Cleaning is performed by spray-in-air at high flow rate but low pressure, to avoid damage to the product and to assure fast and efficient cleaning.

The machine is equipped with a 100% closed-loop filtration system to filter out collected contaminations from the cleaning agent. It can optionally be equipped with an demi-water rinsing process that can be either openloop to the drain or closed-loop with integrated demi-water filters.

After the cleaning cycle, products can be dried with the integrated hot air blower. An optional air knife can reduce the amount of remaining liquid prior to this drying step.

For perfect cleaning results, Partnertec and MBtech recommend cleaning agents from Zestron, the leading supplier in our industry. Zestron offers a wide range of chemistries, including aqueous products with no flash-point and very low VOC content to meet today’s economic and environmental demands.

Contact us to share you cleaning challenge and let us recommend the right solution.