Just before summer we signed a distribution contract with Modi GmbH from Germany. Modi is the market leader for incoming goods scanning systems for the Electronic Assembly industry. Their scanning tables make it very easy to check and re-label incoming goods..

All important data on delivery notes and manufacturer/vendor labels is collected and checked against expected data in the ERP system and ASN (Advanced Shipping Notification) Goods are relabeled with a customized label containing a Unique Identifier (UID). This UID can be created by the MODI software

or collected from the customers ERP. UID’s link to all relevant data, such a part numbers, batch and lot ID’s, MSD information, production and expire dates, Quantity on the reel etc. Unique Identifiers are indispensable for traceability and stock transparency.

What does a Modi system offer:

• Avoid misplacements and expensive rework due to wrong labels.

• Avoid unexpected component shortage and line-down time.

• Provide complete information for component level traceability.

• Data for Full stock transparency, what is located where and in what quantity.

• Process time Reduction for incoming goods scanning/relabeling.

• Avoid human mistakes when hand scanning multiple barcodes.

• Improve overall efficiency.

The method

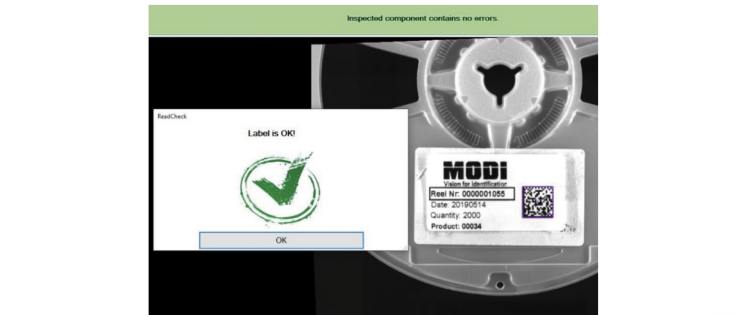

Operators simply place components on the Modi work table and the integrated camera system reads the barcodes on the reel. Once all data is collected, checked and stored, a new barcode is presented to the operator, that must be attached to the reel. Then the system will check if the label is correctly mounted

and fully readable. This entire process will only take a few seconds. Fully automated Modi systems using robots and transport belts are available too, for further reduction of operator time.

The technology

Modi uses a patented ADOMO scanning system based on two cameras and a moving mirror. One overview camara scans the entire reel for available labels and barcodes. The powerful software will automatically determine which barcodes are relevant. A second more accurate camera looking via a moving mirror will than focus on relevant barcodes and collect required information. Focusing on a smaller area requires less computer data and improves the reading process.

The software

Over the last 20 years Modi has developed a powerful software in a SQL database structure, using modern web service based integration with ERP/MES systems and Pick & Place machine software. Advanced algorithms including OCR (text recognition) will assure that all data can be collected from any

kind of label used in our industry.

More information?

Please contact us if you wish to learn more about how Modi can help your organization to improve quality and become more efficient.