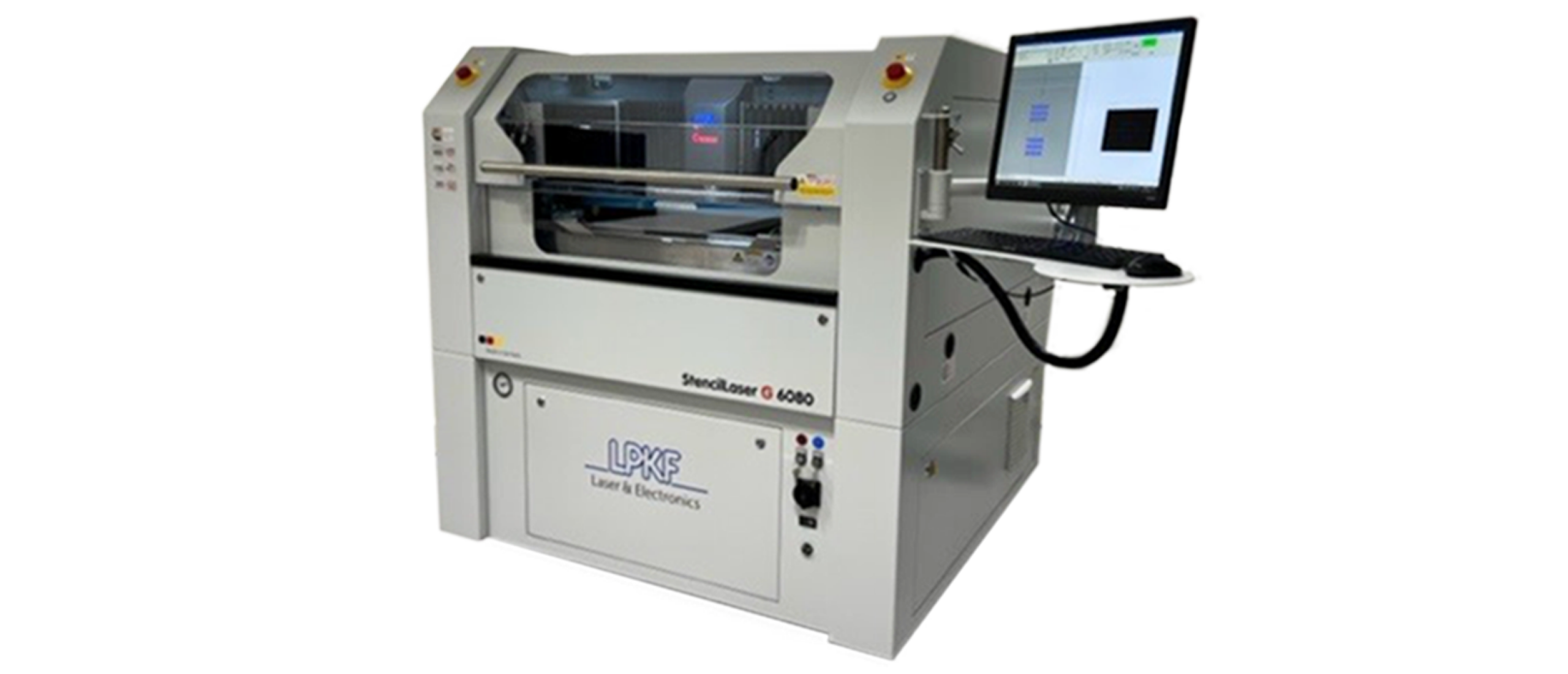

To meet projected demands in the years ahead, Partnertec is investing in people and High Tech production equipment. This new state of the art LPKF laser cutting machine for stencil fabrication is a major step forward.

Partly due to a strong growth in our stencil production and further expansion of our stencil department, Partnertec has recently invested in the latest state of the art laser cutter from LPKF Laser & Electronics AG.

This high speed and high yield production machine from LPKF is not only extremely accurate (2 um) but is also capable of locally applying different thicknesses to a stencil by means of nitrogen laser welding, also known as Step Stencil Technology.

The Innovative variant of the high-end LPKF Stencil laser system sets new benchmarks in two dimensions: Extremely small openings of the highest quality enable new stencil applications and precision parts to be manufactured with the highest precision of stainless steel sheets in a range of 30 um up to 1000 um thickness.

From our (new) location in Eindhoven we are now even better able to supply more flexible, faster, and above all, a higher quality laser cutted stencils ranging in thicknesses from 80-250 um with max frame sizes of 740x1800x40 mm and a cutting range of max 600x800 mm.

For more information please contact stencils@partnertec.nl or our manufacturing department.