Conformal coatings protect printed circuit boards (PCBs) from moisture, corrosion, contaminants, vibration, and thermal shock. Coatings are a complicated science, and there isn’t one best coating or application method for every job. It depends on the design, use case and assembly.

Regardless of the chosen method, fundamental application errors can occur, leading to defects in the coating, which ultimately limit the functional service life of the PCB.

Most common problems in conformal coating application

The printed circuit board industry is rapidly evolving, leading to two major trends causing issues with conformal coating application:

1. Increased Board Density: Boards are more densely packed with shrinking space between components and component leads. Conformal coatings need to flow and distribute evenly across components for proper protection. However, natural surface tension behaviors, such as adhesion and cohesion, prevent the material from flowing properly when space is tight. Common issuesin coating applications include:

• Bubbles forming in the coating

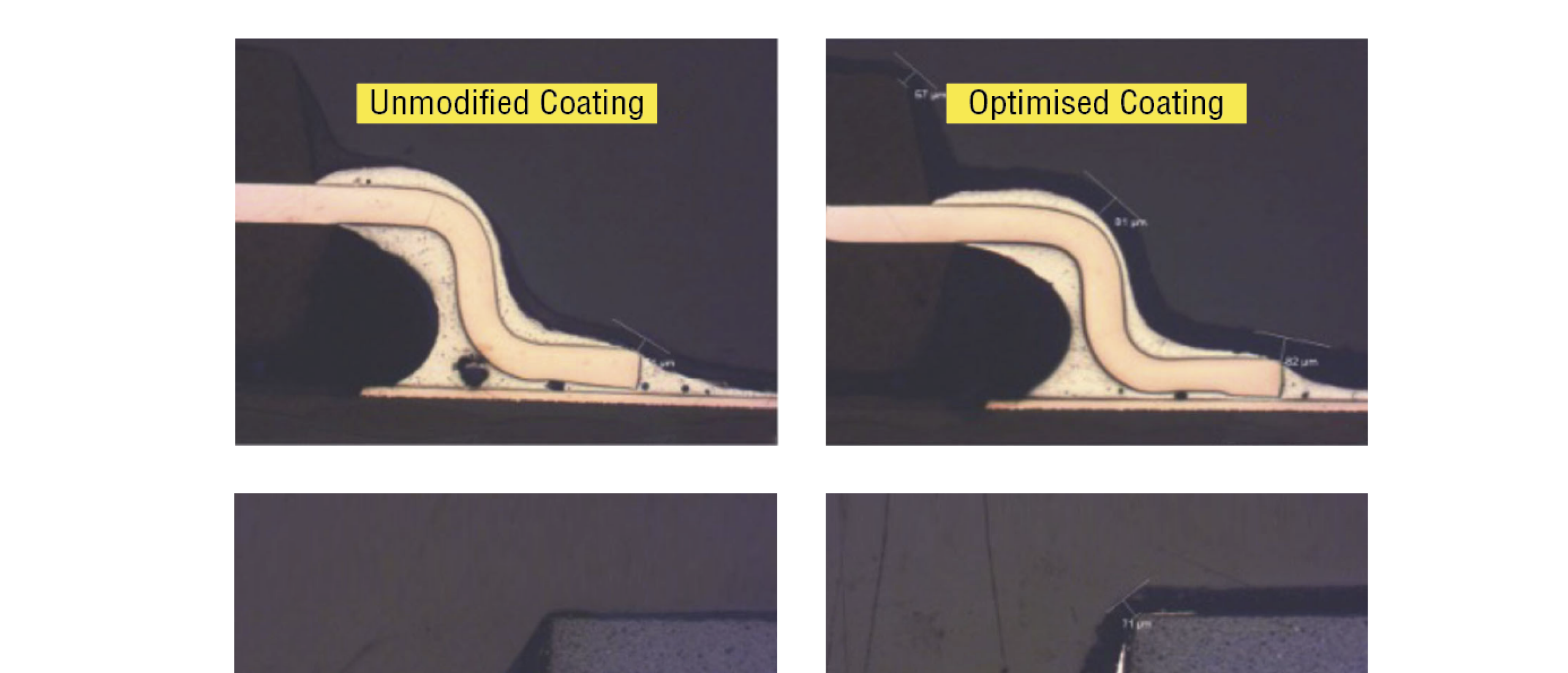

• Too much or too little coating spread around sharp corners

• Defects emerging during intense thermal exposure

2. Higher Performance Expectations: The performance expectations are more demanding,

requiring even better protection from coating materials than ever before.

How does Humiseal addressthese challenges?

Humiseal continuously conducts extensive research on both coating materials and application methods. In a recently released whitepaper, you can read more about this research and the results achieved: Whitepaper: Conformal Coatings - New Solutions to Existing Problems

New Sharp Edge Coverage (SEC) coating materials

As a result, Humiseal frequently introduces new and improved coating materials, such as those developed for better Sharp Edge Coverage (SEC). A significant experiment was performed during Productronica 2023, demonstrating how much better SEC coating materials perform. Watch the experiment here.

Follow us to receive the latest news!

Follow us to receive the latest news!

<:optin-form-placeholder>

Solving the biggest problems facing modern conformal coating application?

Place comment