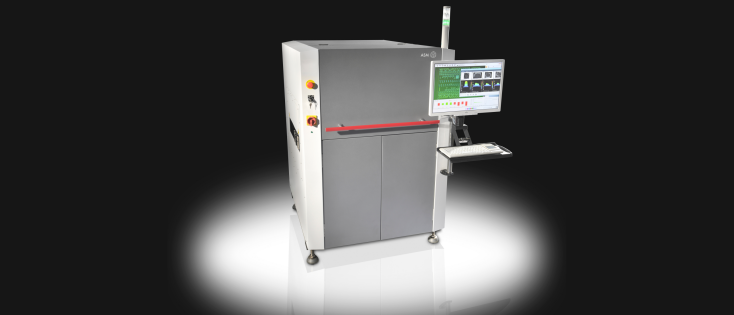

The successor to the well-known Dage Quadra has recently been released. Sold under the new company name, Nordson TEST & INSPECTION (T&I), the Quadra Pro series is now available.

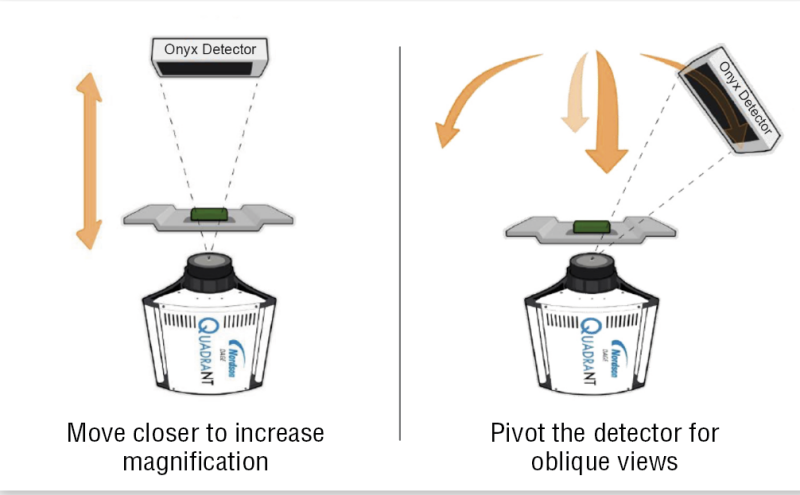

New Onyx Detector

The Quadra Pro series uses the new Onyx Detector, originally developed for the semiconductor industry. It offers higher resolution, lower noise, higher clarity, higher brilliance, and above all, faster frame rates resulting in quicker imaging.

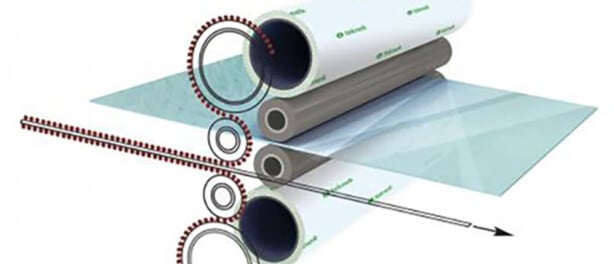

Quadra NT Tube

The well-known “maintenance-free” Nordson Quadra NT tube has been further enhanced, offering dual mode on the Quadra 7 Pro machine. It can switch between “High Resolution Mode” for very sensitive samples and “High-Flux Mode” for denser and thicker samples. The maintenance-free X-ray tube technology, which uses a long-lasting crystal source for generating electrons, remains unchanged. The crystal source creates a more focused electron beam than traditional tungsten filaments, resulting in brighter and clearer images, and the filament does not require replacement, performing consistently over the lifetime of the tube.

New Revolution Control Software

The modular, service-based new software architecture offers divided modules for motion control, image capturing, and tube control. The newly designed modern Graphical User Interface offers simple intuitive menus and easy “point and click” control with advanced filters and image enhancements. Images and software are now displayed on one ultra-wide curved high-resolution monitor. Users can reshuffle and customize the location of menu items on the screen.

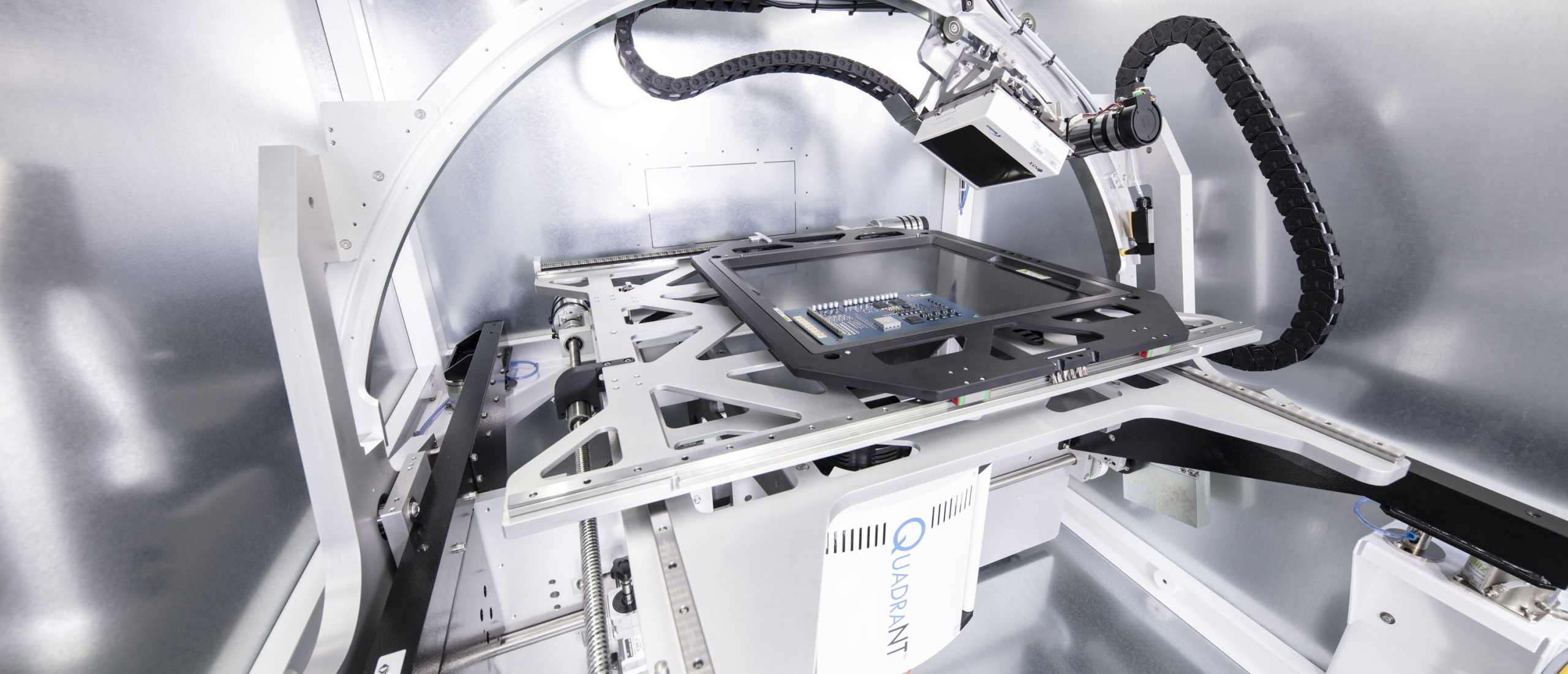

As before, the Quadra Pro series uses the same sample manipulation method, meaning no rotation of the PCB, so the orientation remains the same for the operator while examining a solder joint. The sample moves in X, Y, and Z, while the detector rotates up to 140 degrees in all directions around the sample.

The manipulator can now move at higher speeds, and images are collected faster at a higher quality.

As a result, the popular X-plane CT scan option can now create 3D image information up to three

times faster at any location on your PCB, at any desired magnification.

Cera Reconstruction and Visualization software is now embedded in the machine user interface.

X-plane scans can now be added to the automatic inspection routines.

Available Models

As before, three models remain available for specific demands:

Quadra 3 Pro

• Defect detection on features as small as 0.75 µm

• Perfect for PCB inspection on BGA, QFN, solder shorts,

through-hole filling, and counterfeit components

• 15 Watt X-ray tube

Quadra 5 Pro

• Defect detection on features as small as 0.3 µm

• Perfect for advanced PCB inspections, void measurements, power electronics, finished goods

• 20 Watt X-ray tube

Quadra 7 Pro

• Defect detection on features as small as 0.1 µm

• Ultimate inspection at the semiconductor level, wire sweep, wafer level inspection, failure analysis

• 20 Watt, Dual Mode X-ray tube

In comparison to the previous Quadra models, a Quadra Pro 3 performs at the Quadra 5 level, while the Quadra 5 Pro matches the original Quadra 7 image quality. The new Quadra 7 Pro performs at unbeatable inspection levels never reached before!

Quadra Pro systems can be demonstrated in the Nordson T&I application center in Feldkirchen, near the Munich exhibition center. In this application center, Nordson T&I also demonstrates Autonomic X-ray Inspection systems (AXI), formerly sold under the name Matrix. AXI systems can fully automatically inspect products at very high speed, allowing inline integration in SMD lines and 100% 3D inspection. Nordson T&I also offers X-ray SMD component counters and acoustic inspection equipment. You’re more than welcome to visit and explore the unlimited possibilities.

Nordson T&I now offers attractive trade-in proposals to promote the new Quadra Pro series. Please let us know if you wish to receive more information.

Follow us to receive the latest news!

Follow us to receive the latest news!

<:optin-form-placeholder>

Making the invisible visible | Nordson T&I launches the Quadra Pro Series X-ray inspection system

Place comment